Application products: EXAIR 44th generation ion gas gun

Application target: EXAIR hand-held ion air gun is applied in the paint shop of automobile factory!

Problems encountered by customers:

The hot summer has officially ended, and autumn and winter are getting closer and closer to us, and the surrounding air has become more and more dry. Generally speaking, when the air humidity is relatively high, the generation of static electricity can be reduced, and the dry air is more likely to generate static electricity. In our daily life, the more common electrostatic objects such as our clothes, scarves, carpets, etc., often cause electric shock when the metal door handle is touched. Despite the fact that this static phenomenon does not cause harm, in the industrial production environment, the harm of static electricity is indeed great. It is possible that the electric shock phenomenon that occurs when the metal door handle is in contact with the hand may seem to be simple but may cause quality problems in the finished product, material clogging/tearing, feeding problems, adhesion between products, or adhesion roller or dust adhesion. The product is inferior.

In many coating lines, especially in the automotive industry, dust debris from the surrounding environment can adhere to the parts before painting. At this time, if you choose a standard air gun to remove debris, the effect is almost negligible. It is necessary to remove static electricity before dust removal, otherwise it will cause defects after painting. The consequence is that a large number of parts will be scrapped. I recently visited a customer in the automotive industry, which is mainly engaged in automotive interior parts. These parts are placed on a shelf not far from the spray booth before spraying, and dust is inevitably attached to these parts. It is not enough to use air guns to remove dust. After the completion of the spraying operation, the quality inspection showed that the ratio of unqualified products was close to 60%.

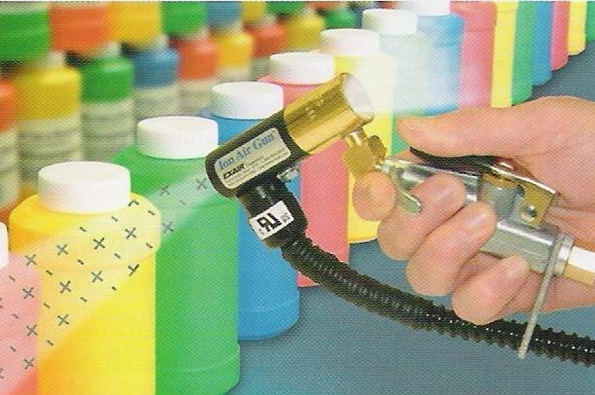

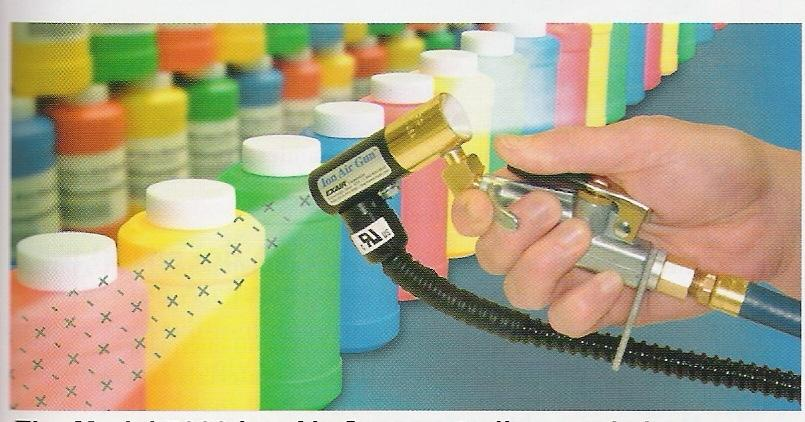

Fourth generation handheld ion air gun

The solution recommended by the United States (EXAIR):

For the specific situation of the customer, we brought a fourth-generation ion air gun model 8193 to the customer for trial, which will replace the ordinary compressed air spray gun that the customer originally used. The ionic air gun of the United States is ergonomically designed and is a low-energy hand-held air gun. We used an electrostatic detector to perform static electricity detection on the front and the back. The results showed that the ion gun had a significant effect on static elimination. The ratio of unqualified products has dropped from the original 60% to the current 10%.

The United States I love static elimination products inventory models are complete and there are a large number of stocks in the US factory, can be shipped by lightning. When we enter the dry winter, the problem of static electricity will become more prominent. Never wait until static electricity becomes a difficult problem before thinking about remediation.

If you are experiencing static problems, please contact our engineers.

Model 4193 fourth generation handheld ion air gun