Application products: US Eyre (EXAIR) super air knife

Application Objectives: EXAIR Super Air Knife for Debris Removal in Automated Machining!

Problems encountered by customers:

An auto parts manufacturer was troubled by debris after completing the part processing. After the various types of auto parts are processed, they will be transferred from the machining center to other places by the robot. When the parts are taken out, the rows of neatly arranged nozzles will be used to remove the residual machining debris. Although it can also play the role of chip removal, when faced with various structures and different shapes, the gap between the nozzle and the nozzle makes it impossible to completely remove the chip debris, and the chip removal effect is unsatisfactory. Therefore, manual intervention must be carried out, which is time consuming and labor intensive. The entire production process is no longer fully automated, greatly reducing production efficiency.

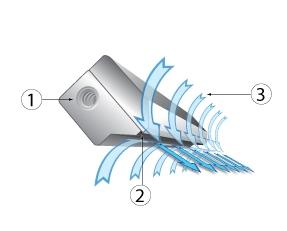

Model 110018 18 inch super air knife workshop in addition to debris work diagram

The solution recommended by the United States (EXAIR):

The United States recommended the model 110018 18" super air knife to be installed and used by this customer. After the parts are processed, the robot grabs the auto parts and passes through the air curtain area of the super air knife to achieve uniform air curtain. Coverage, no manual blow-off. In this customer's application, the United States is the best choice for the Super Air Knife, which can provide up to 18" (457 mm) long and impactful air curtains. In order to improve efficiency and adapt to parts with complex surface structures, it is convenient to adjust the position of the air knife at any time. They also accepted the recommendation of the I Love Engineer to install the 9060 universal air knife installation kit.

Super gas knife working principle:

Compressed air enters the air knife high pressure chamber through the air inlet (1), and the airflow passes through the narrow, thin slit (2) to form a balanced airflow sheet in the longitudinal direction of the air knife. Since the Coanda Surface (3) has a 40:1 magnification ratio to the high-pressure airflow, the airflow velocity loss is minimized and the pressure is maximized, thus producing a sheet of airflow with a strong impact force and a minimum shear force.

If you have troubles in this area, please call us.